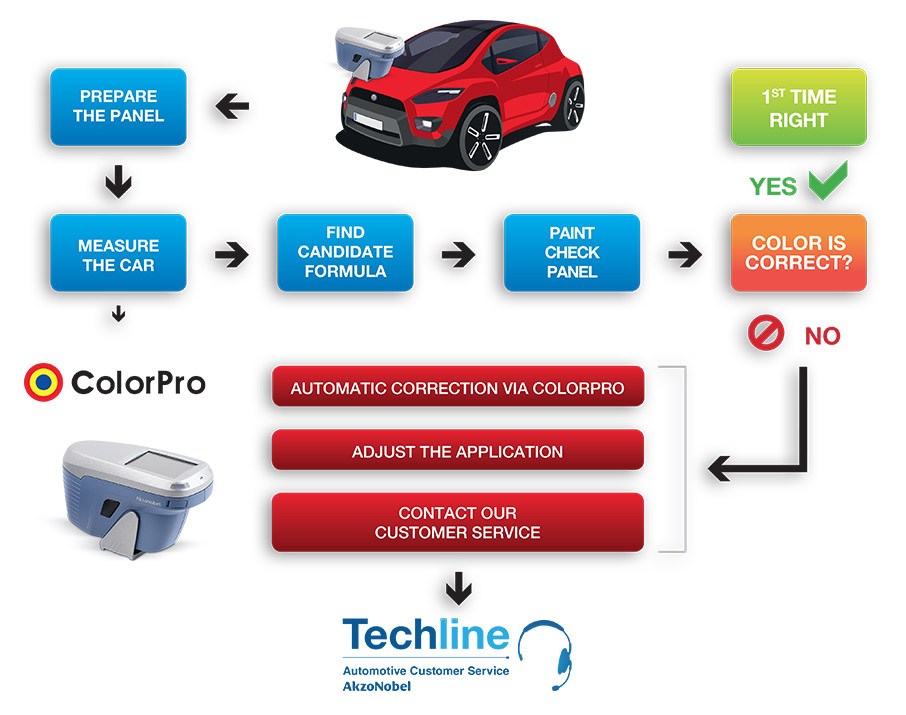

Through a robust color process, we offer in AkzoNobel database more than 3 million color formulas with the most varied and advanced effects. In our desire to “Get the right color at first,” we support our customers because we see them as partners, and one of our most important jobs is to help them produce accurate, predictable and consistent color.

Capturing colors is a complex science, and while car manufacturers provide us with continuous information about their latest colors worldwide, it is up to us to ensure that through our various color collection centers scattered around the world, we have captured the colors and all its variations. In our color development factories, we use the latest technologies to produce Wanda specifically, approximately 16,500 color formulas that we identify each year. It involves creating pigment combinations that will accurately reproduce the new standard colors and their most common variations.

Once the correct color is achieved, the color process leaves the domain of precise digital technologies and enters the art world. The painter and his skill are an incredibly important component to achieve the perfect and invisible repair ideal.

With our research network, color development centers and technical consultants, we offer our customers the most qualified color service, also offering colorimetry and application courses in our training centers. AkzoNobel works constantly to ensure its customers quality and agility through our commitment to provide the right color every time.